A2 steel knife–A2 Steel in Knife Making

A2 steel knife–A2 Steel in Knife Making

So, you’re on a quest for the perfect steel for your knives, and the journey has brought you to the realm of A2 steel. In this guide, we’ll navigate the nuances of A2 steel, exploring its standard, chemical composition, applications in knife making, sizes, prices, and the key players—the A2 steel suppliers.

The Essence of A2 Steel: Beyond the Basics

A2 steel isn’t just any steel; it’s a blade’s best friend. As we delve into the standard and chemical composition, you’ll uncover the alchemy that makes A2 steels stand out in the world of knife making.

Crafting Excellence: A2 Steel Properties in Knives

What makes a knife exceptional? It’s the properties of the steel. A2 steel brings a unique blend of toughness, wear resistance, and edge retention to the table, making it a preferred choice for crafting knives that stand the test of time.

The Art of the Blade: A2 Steel Applications in Knife Making

Knives are more than tools; they’re an art form. A2 steel finds its canvas in the hands of skilled artisans, shaping into blades that excel in various applications—from precision cutting to outdoor adventures.

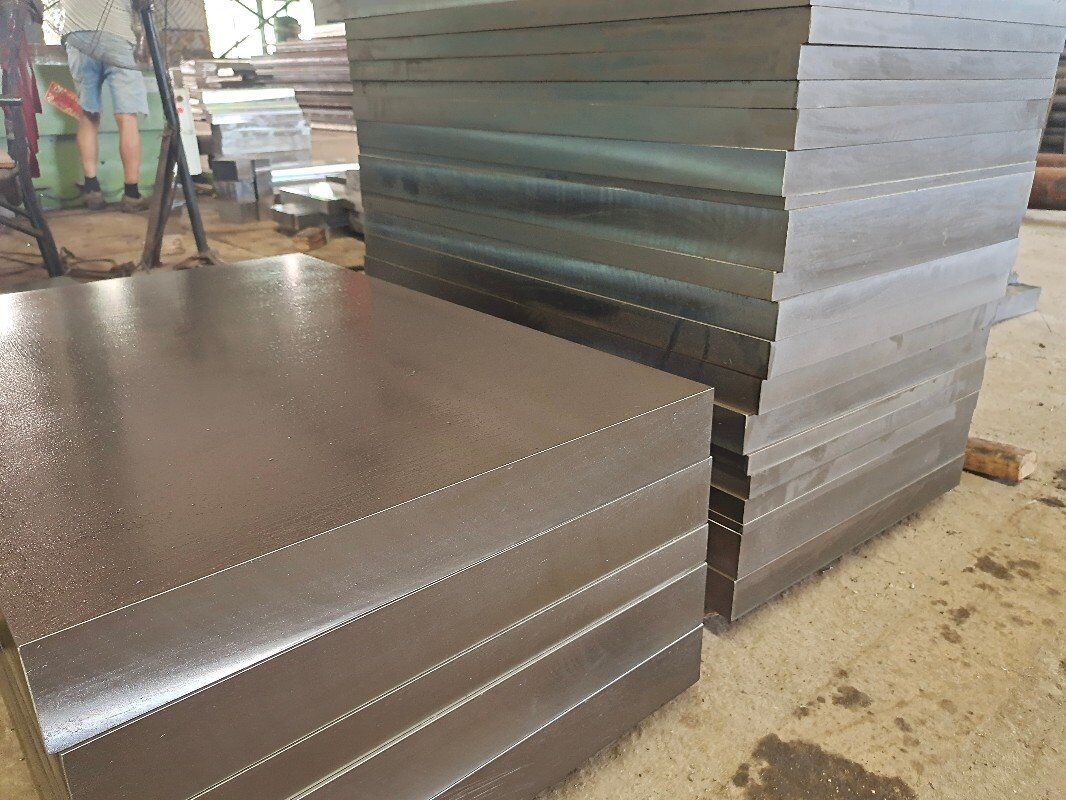

Size Matters: Customizing A2 Steel for Your Blades

Each knife has its story, and A2 steel allows you to tailor that story. Explore how A2 steel can be customized to meet the size requirements of your blades, ensuring a perfect fit for your unique designs.

Unveiling the Price of Precision: Navigating A2 Steel Costs

Numbers can be daunting, especially when crafting something as personal as a knife. We’ll guide you through the factors influencing the costs of A2 steels, helping you make informed decisions without compromising on quality.

Sourcing Success: Finding Your Ideal A2 Steel Supplier

The search for the best A2 steel suppliers is an art. Certifications, track records, and customer reviews become your compass in navigating the market. Discover tips on securing the highest quality A2 steel for your knife-making ventures.

Beyond the Blade: A2 Steel’s Future in Knife Making

The story doesn’t end with today’s knives. Explore potential future trends where A2 steel could play a pivotal role in shaping the knives of tomorrow.

Conclusion: A2 Steel – For Blades That Endure

In conclusion, A2 steel isn’t just a choice; it’s a commitment to crafting blades that endure. From its unique composition to customizable sizes, A2 steel is a canvas for your knife-making dreams.

FAQs: Your Questions Answered

- Why is A2 steel suitable for knife making?

- A2 steel’s balanced properties offer a unique combination of toughness, wear resistance, and edge retention, ideal for crafting durable knives.

- Can A2 steel be forged for custom knives designs?

- While it’s primarily a tool steel, A2 steel can be forged to create custom knife designs in the hands of skilled blacksmiths.

- Is A2 steel prone to rusting in knives?

- A2 steel, while not stainless, offers moderate corrosion resistance. Proper care can mitigate the risk of rusting.

- How do I choose the right size of A2 steel for my knives?

- Consider the intended use of the knives and consult with suppliers to determine the most suitable size for optimal performance.

- What certifications should I look for in A2 steel suppliers for knives making?

- Look for certifications like ISO standards, ensuring quality and reliability in the supplied A2 steel for crafting precision knives.