30CrNiMo8 is a chromium-nickel-molybdenum alloy steel known for its high tensile strength and toughness. Its unique composition imparts remarkable properties that make it a preferred choice in demanding applications.

Chemical Composition

The chemical composition of 30CrNiMo8 steel includes elements such as chromium, nickel, molybdenum, carbon, silicon, and manganese. This combination is carefully balanced to achieve the desired mechanical properties.

Mechanical Properties

Tensile Strength

30CrNiMo8 steel boasts impressive tensile strength, making it capable of withstanding high loads without permanent deformation.

Yield Strength

Its yield strength, another critical property, indicates the amount of stress the material can endure before it begins to deform plastically.

Toughness

The toughness of this steel is a testament to its ability to absorb energy without fracturing, making it suitable for impact-loading scenarios.

Heat Treatment

Quenching

Quenching involves rapid cooling of the steel after heating. This process enhances its hardness and wear resistance.

Tempering

Tempering follows quenching and helps reduce the brittleness that may result from the rapid cooling process, ensuring a balance of hardness and toughness.

Machinability

30CrNiMo8 steel exhibits good machinability, allowing it to be easily shaped and formed into various components.

Weldability

Weldability is a crucial factor in many industries. This steel can be successfully welded, but proper techniques and precautions must be followed to maintain its integrity.

Automotive Industry

In the automotive sector, 30CrNiMo8 steel finds applications in critical components like crankshafts, gears, and axles, thanks to its exceptional strength and durability.

Aerospace Sector

The aerospace industry relies on this steel for structural components and landing gear due to its high tensile strength and fatigue resistance.

Oil and Gas Exploration

In the oil and gas sector, 30CrNiMo8 steel is used in drilling equipment and components that operate in harsh and corrosive environments.

Manufacturing and Machinery

Manufacturers of heavy machinery and equipment use this steel for its reliability and longevity in components like shafts and gears.

Construction and Infrastructure

In construction and infrastructure projects, 30CrNiMo8 steel provides the necessary strength and durability for critical structural elements.

Advantages of 30CrNiMo8 Steel

The advantages of using 30CrNiMo8 steel include its high tensile strength, excellent toughness, and versatility, making it suitable for a wide range of applications.

Challenges and Considerations

While 30CrNiMo8 steel offers numerous advantages, it is essential to consider factors like cost and the need for proper heat treatment.

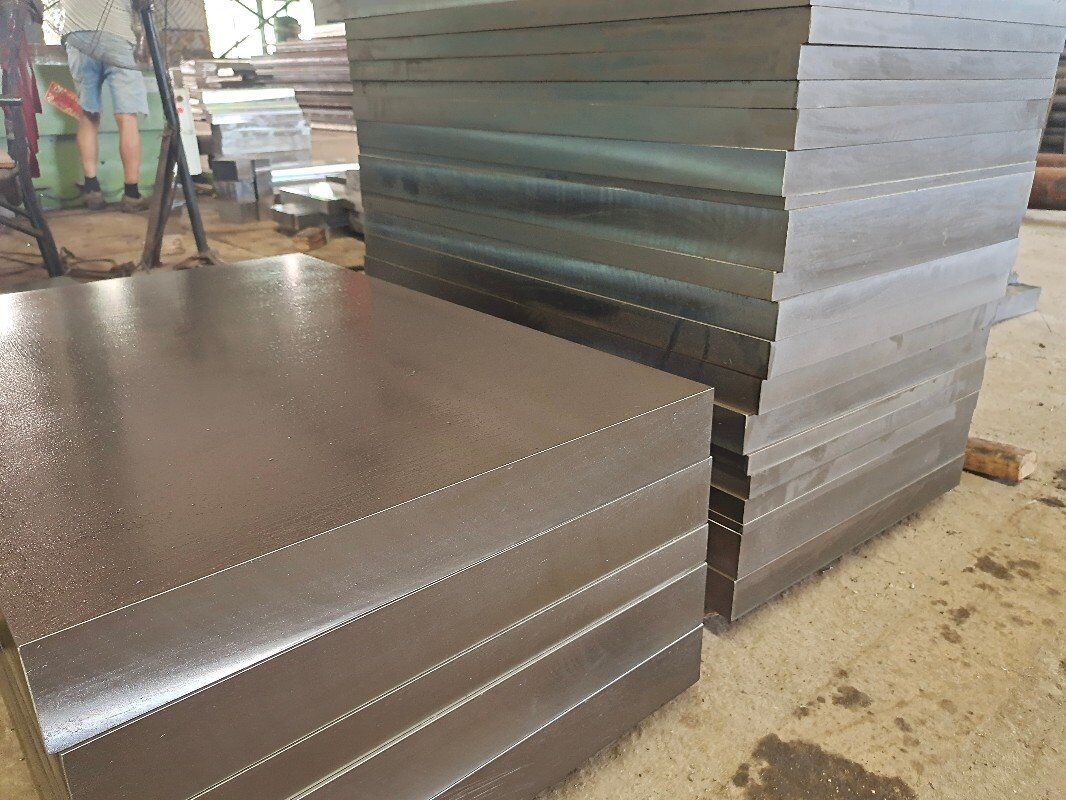

Sourcing and Quality Assurance

Sourcing 30CrNiMo8 steel from reputable suppliers and implementing quality assurance measures are crucial to ensure the integrity of the material.

30CrNiMo8 steel stands as a testament to the potential of alloy engineering. Its remarkable properties and versatility make it an invaluable asset across industries, from automotive and aerospace to oil and gas. Understanding its composition, mechanical properties, and applications is essential for making informed decisions in various engineering endeavors.